It is unknown to the general public, and yet we owe it a lot: it is the meltblown. Here’s what you need to know about this precious filter material that KLAP has chosen to manufacture locally, for its own needs but not only, and that’s good.

What is meltblown?

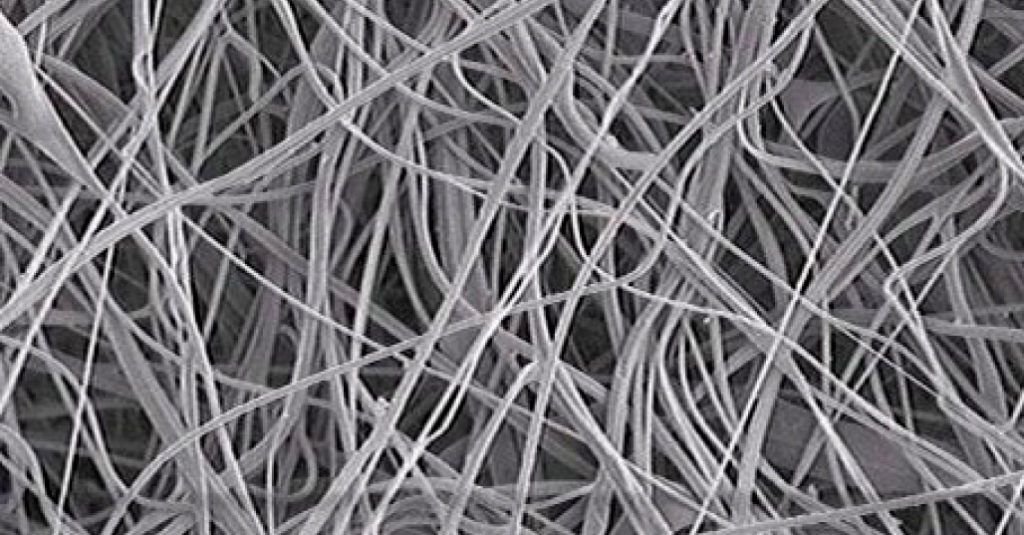

It is a textile material but whose fibers are not woven together unlike conventional fabrics. At the beginning of the manufacturing process, there are polymer beads, plastic derivatives. These beads are melted and blown and then cooled to such a speed that they freeze forming a tangle of microfilaments, until they form a uniform tangle of very fine filaments 0.1 microns in diameter. This is the technique of extrusion-blowing.

Then, we obtain a material of formidable efficiency: it is resistant (more than woven textiles that can relax), it is light (2 times more than cotton), it is breathable and, above all, it is filtering. Splashes, dust, vapors, fumes, aerosols carrying bacteria and viruses: they will not pass!

With such qualities, the meltblown (“melted and blown” for translation) did not lack suitors to make his eyes soft. The construction and automotive industries, for example, commonly use it as an insulating and filtering material.

Finally, the meltblown has become indispensable in the field of disposable health protection. It is used in the composition of surgical masks and FFP2 NR masks as a filter media but also in that of gowns and overcoats, charlottes, sheets and single-use covers, etc.

Klap makes its own meltblown

To sustainably reinvent the single-use sanitary protection industry (including disposable respiratory masks), KLAP had to ensure the independence, proximity and quality of its production.

For this, a priority: to produce our own filter media. With an ambitious and forward-looking investment, KLAP has acquired a meltblown manufacturing machine at its production site in Ploufragan, Brittany. Our project was one of the 10 selected by the French State with the aim of structuring a sector for the manufacture of filtering raw materials on a national scale.

Thanks to our meltblown production, we can now ensure our customers the security of supply of our products that do not depend on the vagaries of a sector outside Europe. In addition, we control the quality of our entire manufacturing chain, from the raw material to the finished product. Finally, we guarantee a short circuit, from production to delivery of our products, which thus display an excellent carbon footprint.

And to go even further: we are working on the development of a recycling sector that supports, from their collection to their recovery, a wide range of disposable polypropylene health protection equipment of which the meltblown is made.

KLAP wanted to build an independent, responsible and visionary approach at the service of its customers. The manufacture of the meltblown is a witness to this ambition.